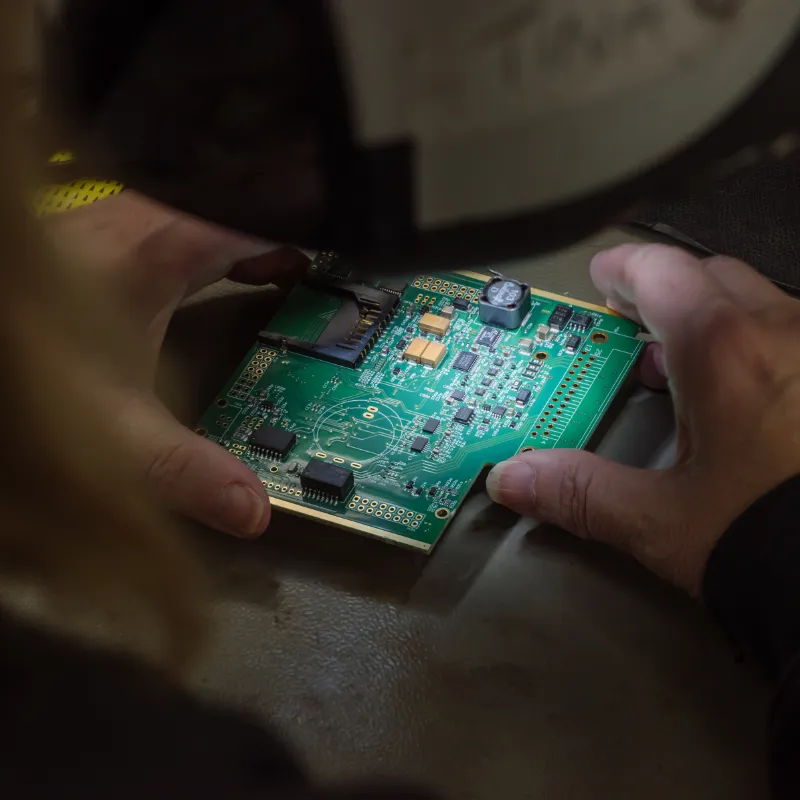

PCB Assembly

FermionX has an extensive PCB assembly service capability which allows us to successfully support from basic to the most complex circuit design, tailored to suit your requirements.

Our PCB (printed circuit boards) assembly services include:

- Surface mount assembly

- Conventional PCB assembly

- Sub-assemblies

- Quality control

- Full inspection and test

We have developed stringent controls to help identify areas to streamline electronic contract manufacturing procurement. This means our customers benefit from price stability and a reduced number of components to stock and manage.

Our PCB Assembly Services

Our PCB assembly manufacturing process is built for flexibility.

We support complex electronic designs, using our surface mount technology to place anything from 01005 resisters to an FBGA with 896 balls. As well as offering traditional thru-hole placement/conventional PCB assembly, we adopt the following methods for our PCB assembly processes:

Surface mount PCB assembly:

We have the flexibility of 3 surface mount production lines to suit a range of product complexities.

Conventional PCB assembly:

Combining the use of our mascot, alongside both selective and flow solder machines to complement traditional hand-soldering

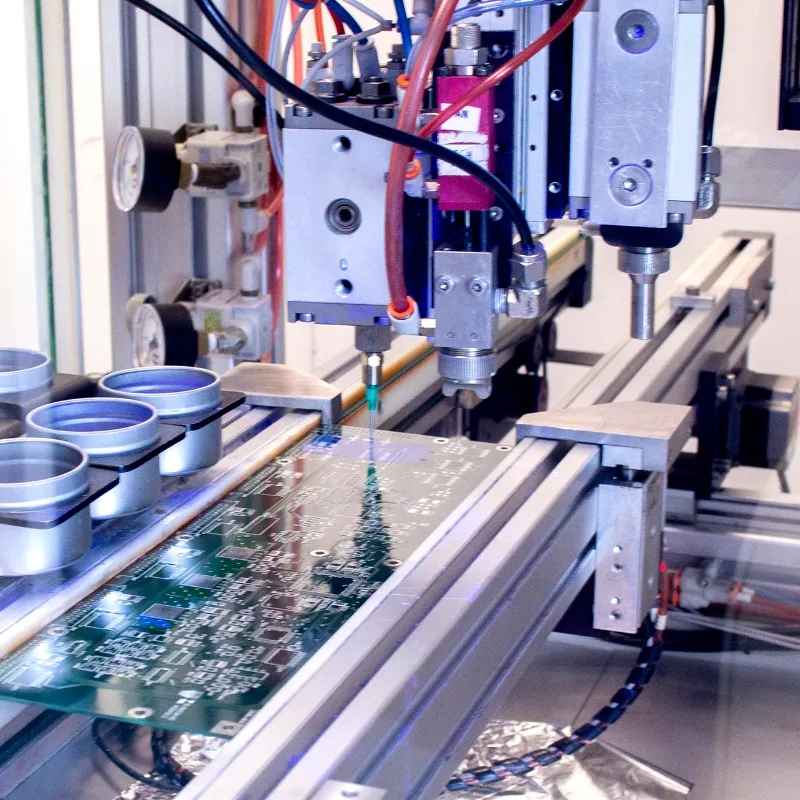

PCB conformal coating:

We have both selective coating machine alongside traditional hand spray-coating. Conformal coating protects components from factors such as moisture, dust, salt, chemicals, temperature changes and abrasion.

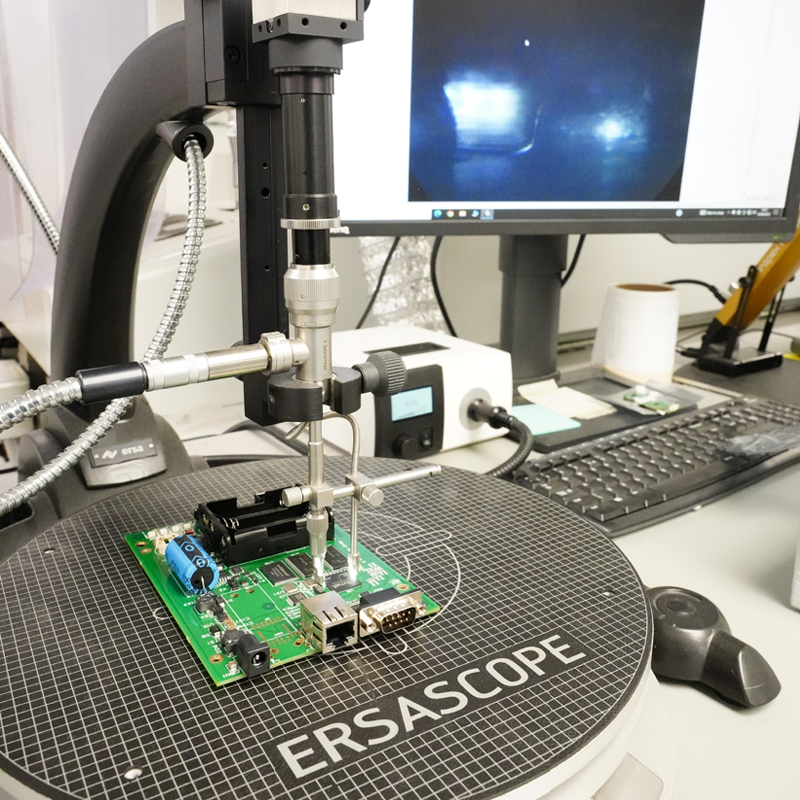

AOI/Visual Inspection:

Boards are inspected using a Mantis or ASH Inspex HD 1080p camera system. As well as an FX 940 Automated Optical Inspection.

X-ray PCB inspection:

For components that can’t be inspected visually due to hidden pads, such as ball grid array (BGA) or quad flat no-lead (QFN). Also used to inspect solder fill/voiding, IC bond wires and PCB tracks/via’s.

Get in touch today to discuss your electronic contract manufacturing and supply chain management requirements.

PCB Assembly Process

Once we have received your completed documentation, your project will be reviewed by our process control manager before being costed via our expert supply chain team. Lead times and component availability will be discussed at this point.

Once the PCB design files have been through contract review and the quote has been agreed, they are then reviewed by our engineering and process control team to finalise data for production.

Our sales and aftercare team are on hand to provide updates and answer any queries during the quote, PCB manufacturing process, and after you receive your PCB products.

State of the art facilities and equipment

At FermionX we’re continually investing in our PCB assembly services, to offer further support to our customers.

Our advanced production facility means we can assemble PCBs and streamline workflow to suit product complexity and production schedules.

We have an extensive plant-list spanning our surface mount and conventional assembly as well as test and inspection capabilities.

View plant listQuality control

For industries with a high degree of regulatory oversight, reliability and attention to detail are paramount. FermionX are committed to maintaining the highest standards of system and process controls. We hold ISO 13485 and ISO 9001 certifications, as well as operating to requirements of ISO 14001.

We have developed a rigorous culture of quality assurance through quality management system. Working proactively to identify and mitigate risks to your supply chain and the production of your PCBA, we offer you the best possible product support.

Industries we work with

The team has a deep understanding of regulatory processes, controls and audit requirements.

This makes us well-placed to support a wide range of industries, including medical device manufacturing and military and defence manufacturing.

Box build and final assembly

We are experienced in all aspects of electronic manufacturing. From simple PCB and cable-fitted sub-assemblies, to integrated enclosures with electromechanical assembly. Our box build service provides solutions to fit your specific requirements.

Our advanced production facility means we can assemble PCBs and streamline workflow to suit product complexity and production schedules.

We have an extensive plant-list spanning our surface mount and conventional assembly as well as test and inspection capabilities.

Request a quote

Speak to our expert team today to find out how we can support you on your next project.

Read our quote requirements here